Things you don't know about wind turbines

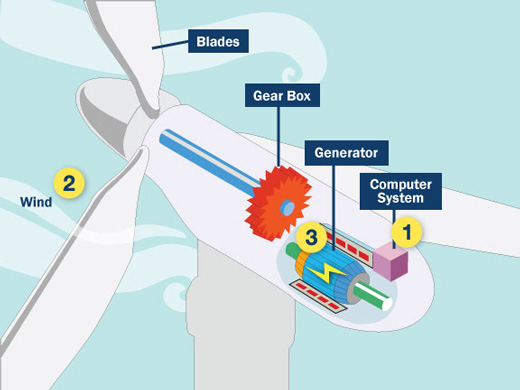

Generally speaking, wind power generation is a process where wind power is converted into mechanical energy by wind turbine, and then changed into electricity by generators. There is a gearbox speeding up the rotation driven by wind power, and promoting the electricity production.

As is misunderstood by many people, wind doesn't “push” the blades to run, but flow over them so as to form air pressure disparity. Such disparity lifts up the blades, prompting them to rotate and constantly transect wind flows. This is the same aerodynamic principle as plane wings.

Based on current windmill technology, wind turbines begin to generate power when wind blows at the rate of 3 feet per second, which is the speed of breeze. As a renewable energy, wind power generation soon gains popularity across the world because it emits no carbon dioxide and reduce our dependence on coals.

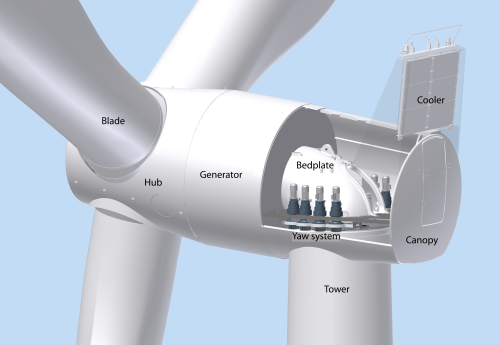

Looked from outside, a wind power generator contains 3 major parts: wind turbine, wind tower and nacelle.

Wind turbines are the main distinction of wind power generator. Composed of 2 or 3 blades and a hub, wind turbine can convert wind power into mechanical energy. The blades of wind turbine are similar to plane wings because they both adopt aerodynamic theories. When winds blow through the wind turbine, there forms an angle between wind and blades where lifting force takes shape and make the blades rotate. In this way, wind generator works and begins to generate electricity.

Wind tower plays an important role in withstanding the weight of wind turbine and nacelle, as well as the wind pressure towards them. Its stiffness determines the vibration intensity of wind turbine. Cylinder and truss are main types of wind tower. Universally, cylinder tower cause less resistance to wind, so the turbulent flow influences are much smaller. Truss tower are applied in middle and mini-sized wind generators. It has advantages in its low cost and convenient transportation. But this type of tower is more apt to cause strong turbulent flow.

Nacelle, the core part of a wind generator, accommodates generator, drive and control system. It plays a role in withstand the outside force, including static load and dynamical load. There is a rotator between the nacelle and tower allowing the nacelle to rotate horizontally. The picture below represents the main structure within a nacelle.

Wind turbine generator is also called induction machine. Using electromagnetic induction principle, generators convert mechanical energy produced by wind turbine to electric energy. The load of modern wind turbine generator is usually from 500KW to 1500KW.

Gearbox is another essential component in nacelles. The low rotate speed of wind turbine can’t meet the requirement of generating power. So there is a gearbox with two spindles on both sides of it, one is connected to wind turbine, the other is connected to generator. The rotate speed can reach up to 50 times through a gearbox.

Yaw system is used to adjust the direction of blades, thus keeping the wind turbine perpendicular to the airflow direction, in which it receives the largest wind power. Yaw system help wind turbine make full use of wind power and increase the generating efficiency. It is controlled by electronic controller, which can detect the wind direction with the help of wind vane.

In addition, electronic controller constantly monitors the condition and operation data of generator, including wind speed and direction, turbine and generator rotation speed, generator temperature and power, current and voltage, etc. When wind turbine reaches their highest speed, or components overheat, the controller will automatically stop the generator, and call operators to debug.

Since wind power is not steady, wind turbines output alternating currents ranging from 13 to 15 volt. They must be rectified by chargers and stored in accumulator jars. By this mean, the electric energy changes into chemical energy. Then, inverters convert it to 220v AC, the voltage used by us in daily life.

After reading this passage, have you understood the working mechanism of wind turbines? As a clean and renewable resource, wind power has attracted global attentions. Wind power generation has also become a promising industry. To meet the growing demand of wind turbine, TICO has designed an innovative wind turbine cranes, which will dramatically improve the working efficiency of wind turbine construction and maintenance.

- single girder bridge crane

- double girder bridge crane

- gantry crane

- jib crane

- portable crane

- wind turbine crane

- Electric Hoist

Demark has made the world’s largest wind turbine, with 88.4 meter-long wind blades. The powe...

As a renewable energy, wind power is clean, economical, inexhaustible and flexible in use. Wit...

Here are 5 wind turbine maintenance methods for common wind turbine failures, including wind t...