double girder bridge crane

The form of bridge crane looks like a horizontally operating single span flat slab bridge whose both ends are supported on two parallel tracks. Double girder bridge crane is an important equipment and tool that contributes to realize the production mechanization and automation in modern industry for lifting and transportation. Double girder bridge crane is widely used in industrial and mining enterprises, iron and steel industry, chemical, railway transportation, port and dock, and logistics.Double girder grab crane

Double girder grab crane is widely used for the bulk cargo loading and unloading in the electric power plant, freight yard, workshop, dock, etc. Electric grab bridge crane is mainly composed of box type bridge, grab trolley, trolley traveling mechanism, the driver's cab and electrical control system. Fetching device is a grab that can be able to grab the bulk material. There is a switching mechanism and lifting mechanism in the grab trolley, the grab were respectively hung on the opening and closing mechanism and lifting mechanism by four wire ropes. Opening and closing mechanism drives grab to close, in order to grab materials. When the bucket mouth closed, immediately start the lifting mechanism, so that four steel wire ropes can do lifting work with the average load. When unloading, only open the opening and closing mechanism, then the hopper is opened, and the inclined material is provided. In addition to the difference of lifting mechanism, the other parts of grab bridge crane is as same as the hook bridge crane.

Electric hoist bridge crane

Electric hoist bridge crane is characterized as the compact structure, low building headroom, light weight, and small wheel pressure. It is widely used for material loading, unloading, maintenance, and transportation in the machinery processing factory, auxiliary workshop of the metallurgical plant, warehouse, stock ground, electric and power plant. It can also replace the ordinary double girder bridge crane, used in the production workshop of textile industry and food industry. The working environment temperature is -25℃ ~40℃, and it is forbidden to use in the flammable and corrosive medium environment. This crane is equipped with two forms of operation: ground control and room operation.

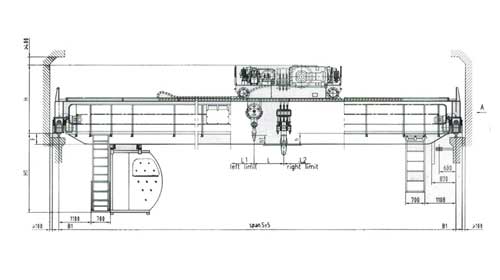

Electric double girder hook bridge crane

Electric double girder hook bridge crane is a widely used lifting machinery nowadays, its mainly composed with box girder, trolley, a trolley running mechanism and an electric control system. The fetching mechanism device is a hook.The main girder is paved with a track, for the horizontal movement of trolley along the main girder direction. Main girder and box girder is welded, there is a joint arranged in the middle of the end girder, connected by joint, for bridge split transportation. There are three forms of operating mode: ground handle, wireless remote control and driver's room operation. This Electric double girder hook bridge crane can be equipped with motor grab, crane magnet, in order to meet the requirements for lifting various of material.

- The lifting capacity of this crane is 3~250t,

- It is suitable for the operation in the factories, warehouse, and freight station where the temperature is -10℃~40℃, and the relative humidity is not more than 85%.

- It is forbidden to operate in the environment where flammable, explosive is, and is filled with corrosive gases.

European series overhead crane with hook

Advantages of European series overhead crane with hook, which is a new generation crane

- Small boundary dimensions , dependable performance, light dead weight, light wheel load and easy to operate.

- The cost of plant construction can be reduced because of Light wheel load and small boundary dimensions, which can save capital investment of lighting, heating and so on.

- Reliable products performance and wear well, which can reduce failure rate and maintenance costs. Not only high quality utilization of the spare parts, but also reduction of the total power can save the cost, it has remarkable energy- saving effect.

Specifications of electric overhead traveling crane with hook cap.75t-100t

| Cap | Main | t | 75 | 100 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aux. | 20 | 20 | |||||||||||||

| Span | m | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | |

| Lifting Height | 24 | 24 | |||||||||||||

| 26 | 26 | ||||||||||||||

| Duty | A5 | A5 | |||||||||||||

| Speed | Main | m/min | 0.37~3.7 | 0.32~3.2 | |||||||||||

| Aux. | 0.57~5.7 | 0.57~5.7 | |||||||||||||

| Crab travelling | 2.92~29.2 | 2.9~29 | |||||||||||||

| Trolley travelling | 4.8~48 | 5.26~52.6 | |||||||||||||

| Limit dimensions | L1 | mm | 705 | 775 | |||||||||||

| L2 | 2075 | 2265 | |||||||||||||

| L | 1070 | 1100 | |||||||||||||

| H | 528 | 428 | 424 | 354 | 250 | ||||||||||

| H1 | 362 | 362 | |||||||||||||

| Main dimensions | H0 | mm | 400 | 500 | |||||||||||

| H | 2335 | 2435 | 2440 | 2970 | 3075 | ||||||||||

| H2 | 2390 | 2540 | 2740 | 2890 | 3040 | 2550 | 2650 | 2555 | 2705 | 2905 | 3105 | ||||

| B | 7700 | 7710 | |||||||||||||

| K | 3600 | 3600 | |||||||||||||

| B1 | 227 | 252 | |||||||||||||

| F | 24 | 174 | 374 | 524 | 674 | 186 | 286 | 190 | 340 | 540 | 740 | ||||

| Max.Wheel Load | kn | 263 | 271 | 279 | 288 | 295 | 305 | 313 | 315 | 325 | 340 | 350 | 361 | 371 | |

| Total Power | kw | 104.5 | 118 | 126 | |||||||||||

| Crane rail recommended | QU100 | QU100 | |||||||||||||

| Power Supply | 3-Phase A.C.50Hz 380v | 3-Phase A.C.50Hz 380v | |||||||||||||

Here is a vadio about our double girder overhead crane, welcome to tell us your requirements.

Get In touch Now!

Product

- single girder bridge crane

- double girder bridge crane

- gantry crane

- jib crane

- portable crane

- wind turbine crane

- Electric Hoist

Demark has built the world’s largest wind turbine

Demark has made the world’s largest wind turbine, with 88.4 meter-long wind blades. The powe...

Advantages and prospect of wind power

As a renewable energy, wind power is clean, economical, inexhaustible and flexible in use. Wit...

5 common wind turbine failures and maintenance

Here are 5 wind turbine maintenance methods for common wind turbine failures, including wind t...